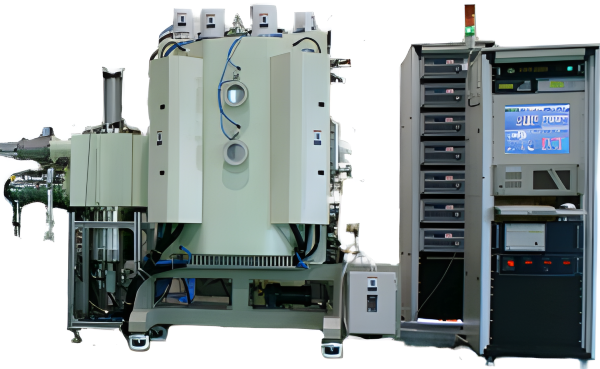

A-Tech System focuses on semiconductor, flat panel display and wear-resistant coating industries. Since 1995 A-Tech System has developed and shipped sophisticated processing equipment for Physical Vapor Deposition (PVD) and for depositions of graphene,

diamond-like carbon (DLC) and carbon nanotube (CNT) materials.

The company bases its designs of PVD systems and sputtering sources on computer simulations as well as on extensive experiences. A-Tech System is therefore highly flexible and capable of responding to customer applications demands in various fields. All A-Tech System products are designed, assembled, and pc-programmed with customers in mind. Processes are evaluated onsite together with customers before tool shipping.

A-Tech System offers tools for many applications, including:

1. PVD

Sputtering Systems

- Versatile magnetron sputtering R&D systems for various fields (ex. Flexlab System 100-including a load lock while remaining highly cost competitive)

- UHV magnetron sputtering systems for deposition of high purity materials (ex.UHV Sputter-100M)

- Reactive magnetron sputtering systems. for ophthalmic lens coatings (ex. OpticalLab-150s)

- lon beam sputtering systems for precision optics (ex. IBS-200F)

- Inline sputtering systems for flat panel display R&D purposes (ex. SPT-370)

- Hybrid systems of sputtering and ion beam evaporation for precision mold coatings (under NDA)

Arc Ion Plating Systems

- Wear-resistant coatings of TIN, CrN, TIAIN, etc. for mold and tool coatings (ex. Vacuum Arc Pilot-12H)

2. CVD

Clustered and/or standalone systems

- Available for grapheme, DLC & CNT depositions. Such systems have been shipped to leading research institutes in Asia.