SPEC

SPEC: Electroless Plating Systems and Wet Process Equipment

Semiconductor Process Equipment Corporation (SPEC) designs and manufacturers wafer and device-level wet process equipment for the semiconductor industry and for other industries requiring high levels of processing cleanliness. Each system is custom designed and manufactured to fit the unique needs and requirements of our customers. Additionally, SPEC’s systems are designed to meet the guidelines noted in SEMI, ANSI, OSHA, NFPA and NEC specifications and standards.

High capacity 200mm automatic wet process system with spin dryer

300mm Cassette-less Final clean tool with slow-pull IPA dryer. Advanced features include dual Isoports and ozone injection

SPEC is experienced in designing equipment that operates within a clean room environment. Process compatibility with materials used in the construction is a high priority at SPEC. Only the highest grade materials possible are chosen to ensure that chemical interaction does not degrade your process. All SPEC’s systems are manufactured in Valencia, California. Final assembly and testing of all systems is completed using clean dry air and de-ionized water in SPEC’s clean room.

Electroless UBM for Pd+Ni+Pd and Zn+Ni+Au

SPEC is the worldwide market leader in Electroless Plating Systems for Under Bump Metallization applications. SPEC’s electroless systems are being used for production by several leading fabs in both the United States and in Asia.

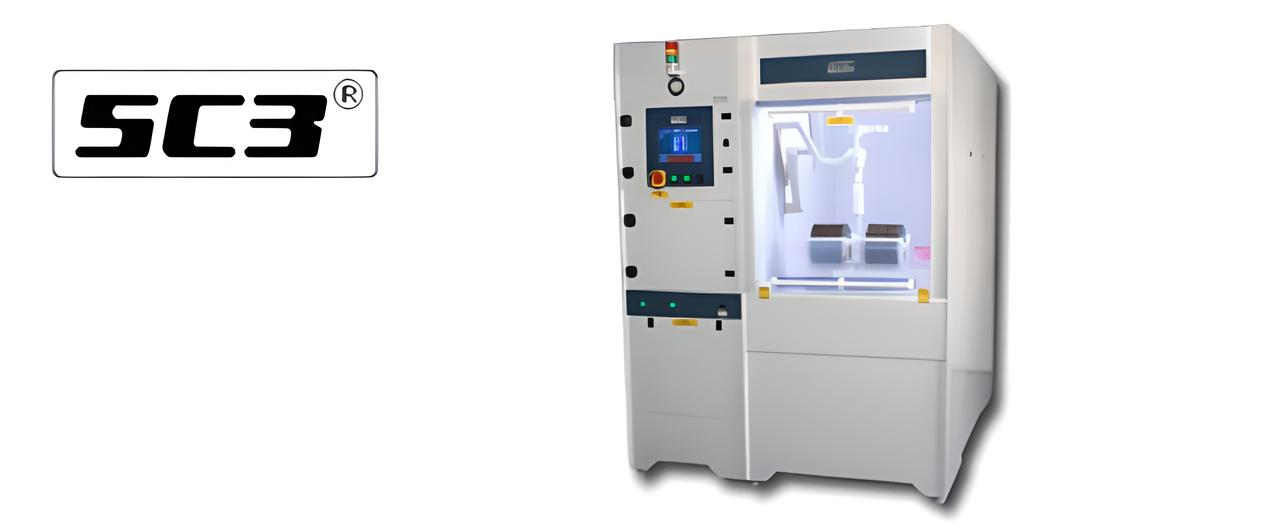

Semiautomatic systems such as the SC3™ provide cost-effective and compact solutions to difficult process situations. The complete pre-diffusion clean is accomplished in less than 30 square feet. Oxide is stripped, SC-1 takes of organics and particles then SC-2 pull metals off the surface. Full computer control and the ability to handle multiple wafer sizes makes this versatile tool perfect for many fabs.

SC3TM Semiautomatic Systems