Vakuum Servis

Company Profile:

Vakuum Servis s.r.o has been operating for more than 30 years in the fi eld of vacuum technology, vacuum deposition and helium leak detection. The company is also engaged in sales of vacuum equipment, servicing of rotary, dry, turbo and diffusion vacuum pumps, design and manufacturing of various vacuum systems, and helium leak detection systems.

Product:

1、Vacuum equipment

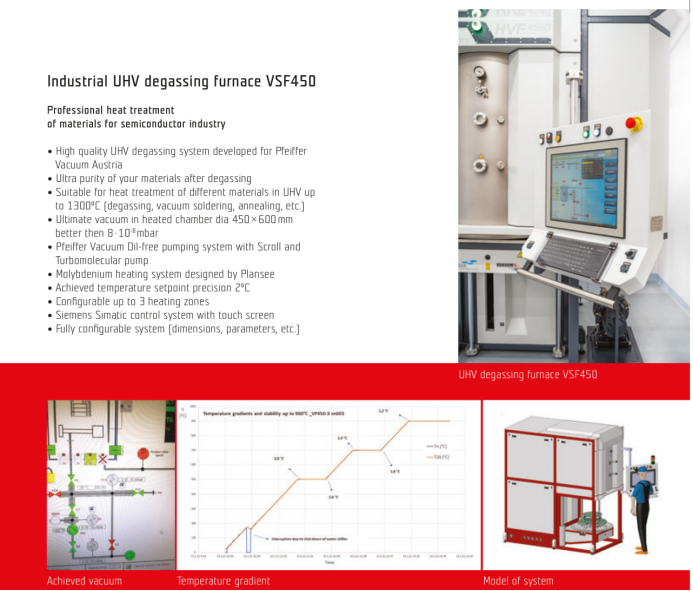

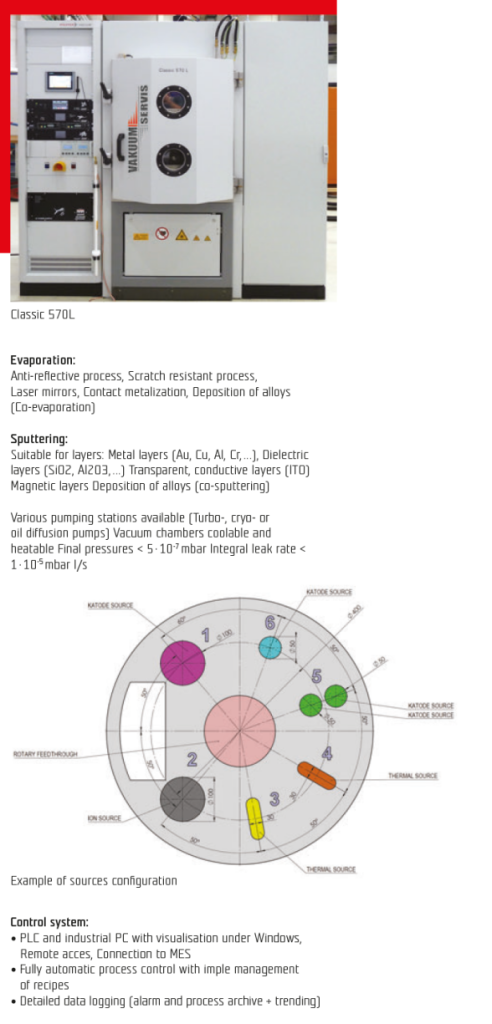

Design, development and production of vacuum furnaces, coating systems, industrial HLDS, customized vacuum systems.

RGA 160 testing system

| • Multipurpose testing device for RGA analysis of UHV components. |

| • Quantitative outgasing analysis for hydrocarbons, water vapour and other specific chemicals , based on customer needs. | |

| • Measurement method based on ASML standard GSA 07 2221 | |

| • Dedicated control software with fully automated measurement cycle with fi nal acceptance protocolin pdf form. | |

| • Possibility of fi nal plasma cleaning and vacuum bakeout of vacuum components before measurement. |

Technical details — standard version

• Oil-free vacuum pumping system with trubomolecular pump and primary scroll pump

• UHV DN160 CF cubical chamber with internal volume of 7 litres

• All-metal vacuum valves

• Quadrupole mass spectrometer Pfeiffer Prisma Pro,mass range 0-200 amu, Faraday +C-SEM detector,open type ion source with Y2O3 iridium fi laments

• Calibration gas mixture included

• Integrated heating for automated system bakeout,(temperature can be adjusted up to 130 °C)

• Ultimate pressure up to < 5e-9 mbar (for empty chamber,after 24 hrs bakeout)

• Minimal detectable leakrate < 5e-7 mbar.l.s-1 for H2O;

< 5e-10 mbar.l.s-1 for CxHy

• Footprint 850 ×750 mm

2、Leak detection, analysis